Plant waste to be transformed into food at new lab in Lund

Lund University and Tetra Pak Processing are joining forces to build one of the largest precision fermentation research facilities in the Nordics. Microorganisms will be selected, fine-tuned and trained to convert inedible waste into food and materials for a growing population.

– Published 19 December 2023

The term “precision fermentation” is being used increasingly by biotechnology and food experts. As resources dwindle and competition for them increases, new solutions are needed. One is to let microorganisms – yeasts, fungi and bacteria – do the work.

“The industrial and agricultural sectors generate incredible amounts of waste with good nutritional content that are currently discarded or, at best, turned into animal feed. Expect the food of the future to be manufactured in a completely different way to what we are used to,” says Eva Nordberg Karlsson, professor of biotechnology at Lund University.

This is how it works: Specially selected microorganisms are added to a pile of unpalatable and hard-to-chew plant parts left over from industrial and agricultural processes. If the microorganisms develop an appetite for the “goo”, two things happen: first, they chew up the mass, and then they spit out beneficial (prebiotic) carbohydrates to our human taste.

At the same time, the number of microorganisms multiplies, which increases the protein content as microorganisms are usually made up of half protein. Some bacteria also grow on carbon dioxide from the air. Once the microorganisms have finished “eating”, what is left can be turned into nutritious and hopefully tasty food!

A new take on an ancient method

The method is essentially an ancient one. Fermented vegetables are based on the same principle. The difference here is that the process does not occur by itself but is controlled down to the last detail.

“One problem we have today is efficiency. The organisms often produce too many products or products that are too diluted, resulting in high manufacturing costs,” says Eva Nordberg Karlsson.

To make modern fermentation a realistic option, better control of the entire production chain is needed. From finding and optimising the best organisms to creating an environment in which they can thrive, and knowing how to scale up so that the result is attractive in the open market.

Several microorganisms are being genetically modified to save time and improve accuracy. However, researchers are also working on variants found in the wild.

For decades, Lund University has conducted research on converting waste products into bioethanol and platform chemicals, i.e. the building blocks for new materials made from renewable raw materials. Tetra Pak Processing, headquartered a few hundred metres away, has expertise in upscaling and packaging.

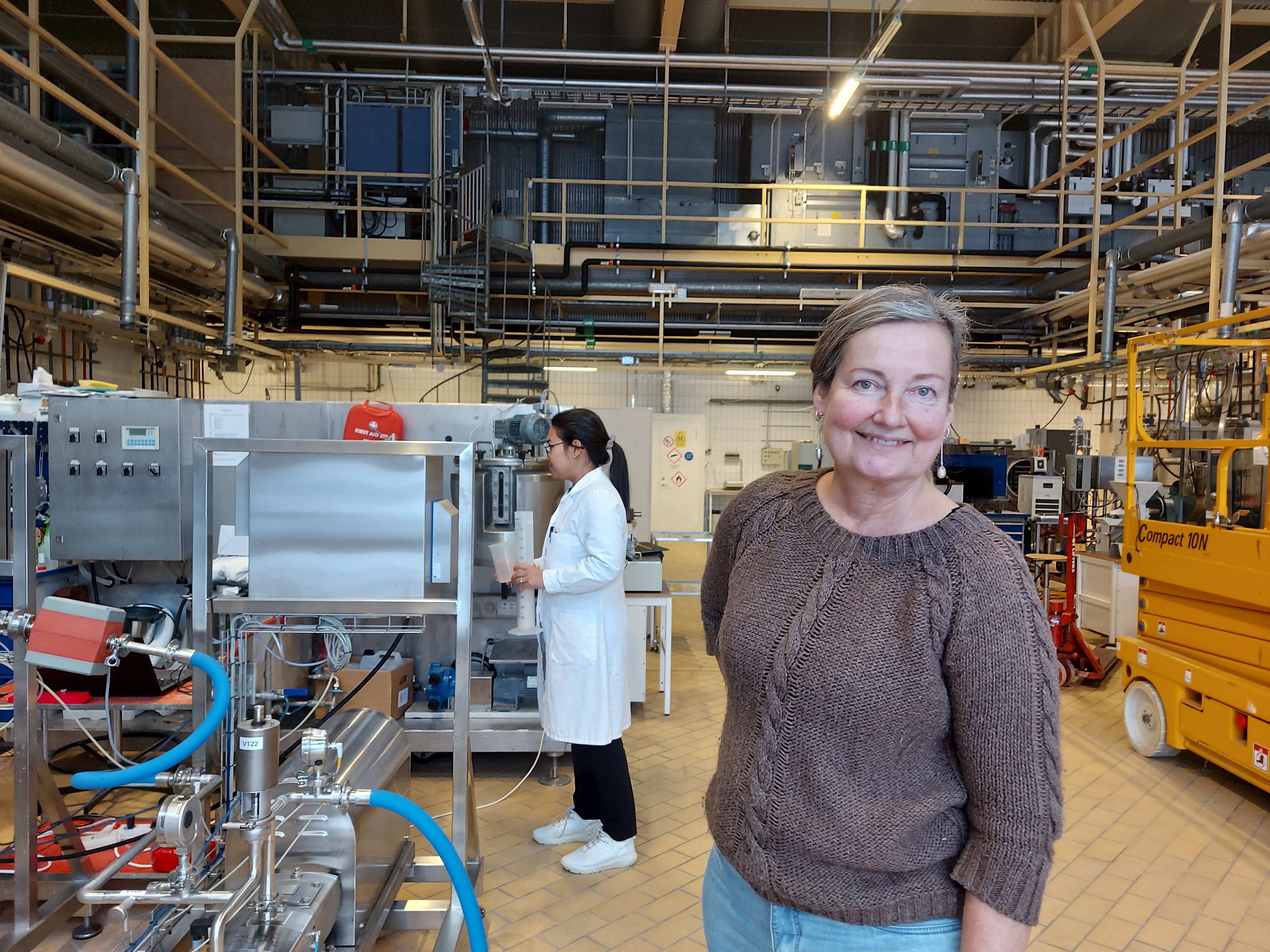

Eva Nordberg Karlsson studies a fermenter where microorganisms are grown.

To be used by many

The two organisations are now working together to build a large laboratory that can handle large volumes and will house different types of tanks, separators, filters, centrifuges, spray dryers and other equipment. The initiative has been named Biotech Heights. The lab will be located somewhere between LTH and Tetra Pak, potentially at Kemicentrum, the Centre for Chemistry and Chemical Engineering at Lund University. The facilities are to be open for other collaborative partners to use.

Only time will tell how much funding will be available. Lund University and Tetra Pak want to involve more partners. Since the news was released a few months ago, Vinnova has granted the project SEK 3 million in funding. Eva Nordberg Karlsson is confident that more people will contribute:

“Lund University is located in the centre of a rich agricultural landscape and there is a large concentration of food manufacturing companies here.”

Precision fermentation

Microorganisms are programmed to produce proteins, fats, acids or carbohydrates, which in turn can be used in food and drink. To be usable, the ingredients should be healthy and tasty and their production efficient.

Three advantages of precision fermentation:

- Land is cultivated more efficiently than is currently the case, as more parts of the plant are put to use. One consequence of this is that more land can be made available for biodiversity

- Reduced need for animal-based food

- Increases the chance of producing plant-based food with good flavour and texture